text, drawing and photo by Phil Bonzon, MMR

In 1946, four class P-7 Pacific’s were streamlined at the B&O Mt. Claire shops for service as P-7d’s on the Cincinnatian train operating between Baltimore and Cincinnati. The “Cincinnatian” has been imported as a brass engine and occasionally one is found for sale, but at prices beyond my engine budget, so I choose to build one. My steam locomotive started as a Bachmann Spectrum Penny K-4, 4-6-2 that I modified to closely capture the appearance and features of the B&O 4-6-2, P-7d (Cincinnatian) number 5301. The Penny K-4, USRA heavy Pacific and the B&O P-7d were very similar in size, wheel size and wheel spacing (MR Cyclopedia-Volume 1, Steam Locomotives, by Linn Westcott); therefore the K-4 is a good starting point for modeling the P-7d.

Construction

Engine

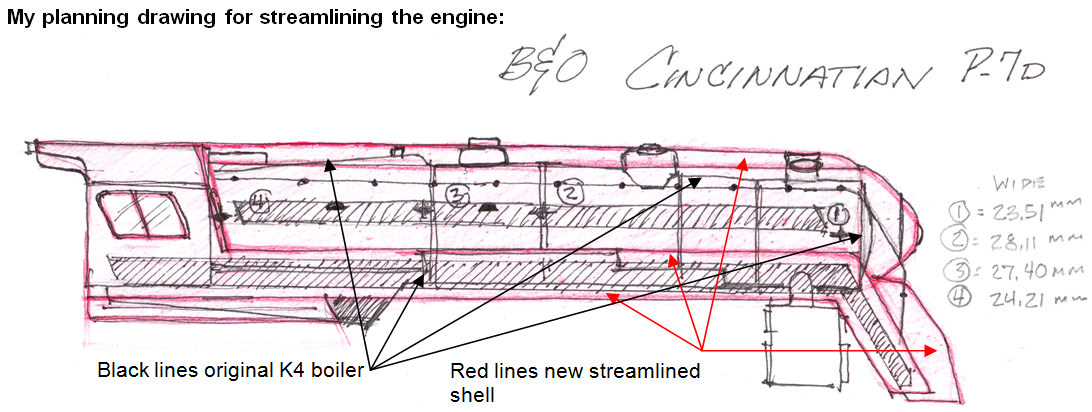

Like the prototype, I started with an existing frame/boiler and clad over the existing boiler with a new scratchbuilt streamlined cladding, pilot, smokebox front and cab. First the engine was disassembled and the Belpaire firebox was ground off; then that area was covered with a layer of 0.010-styreene sheet; length-wise stringers/running boards were made from styrene strips; a styrene disc was made and applied to the smokebox front; all of which served as guides/supports for the new 0.020-styrene boiler wrap that was bonded to the ‘stringers’ with plastic solvent cement and clamped in a vise to hold it shape while drying. The sand dome was removed, reshaped, rotated 90 degrees and reinstalled. The air pump was removed from the side of the boiler because on the B&O it was in the streamlined pilot.

The smokebox front was formed from multiple layers of styrene sheet discs bonded together, sanded to shape and the gaps filled with plastic putty and sanded to final shape; a hole was drilled to accept a styrene tube for the headlight. Styrene Filler plates were added between the stack and the domes, also between the domes and the valves. Steps were cut into to the sides of the boiler cladding with a #11 X-Acto blade and the gap between the new cladding and the old boiler were filled with plastic putty.

The cab and side skirts were fabricated from 0.040-styrene sheet and bonded to together with plastic solvent adhesive. Holes for handrail stanchions were drilled through the boiler cladding to accept the stanchions from the Bachmann engine.

The pilot and steps were fabricated from various thickness of styrene sheet and bonded together with plastic solvent adhesive. Then sanded smooth to blend together.

The cab roof was made from 0.040-styrene sheet formed to the curved shaped and bonded to cab sides with plastic solvent adhesive.

The trim strips and window frames were made from 0.020-brass wire that I annealed, bent to shape, soldered together and bonded in place with CA adhesive. All handrails were formed from 0.020-brass wire. Brass grab irons fabricated and installed on the boiler. A Cal-Scale brass B&O Capital Plate was added to the pilot, as were classification light to the smokebox.

Tender

Working from the prototype drawing and photos, I scratchbuilt the tender body and frame from styrene sheet and shapes that were bonded together with plastic solvent adhesive. ½” diameter styrene tubing was slit lengthwise to form the curved top edge. The curved roof over the recess was formed from 0.030-styrene sheet.

The top deck of the tender was made from 0.020-styrene sheet and is removable for access to electronics. The steps, handrails, ladders, cut lever, brake gear and coal bunker doors were reused from the Bachmann tender and installed on the new body. A Kadee coupler was installed and Precision Scale’s brass Commonwealth six-wheel brass tender trucks were assembled and installed. Also, Cal Scale’s brass air-hoses and steam line were installed.

Electronics

This Bachmann engine did not have DCC or Sound; I discarded the PC boards and lights, then installed a NCE motor decoder and MRC sound decoder in the tender, which I hardwired to the engine. Also, I installed a LED headlight and LED tender backup light. The tender wheels and the engine drivers provide electrical pickup.

Finish and Lettering

The engine and tender were primed, using an airbrush, with Floquil enamel Primer; then Floquil Engine Black was airbrushed, the black areas masked and then airbrushed with Floquil Dark Blue. The handrails, trim and window frames were given a brush coat of silver enamel. The entire engine/tender were airbrushed with Floquil Clear Gloss enamel in preparation for decals. The road name, Cincinnatian signs and numbers, I generated on my computer and transferred them to decal paper and applied them to the model. Model Graphics dry transfer silver stripes were applied. The model was again airbrushed with Floquil Clear Gloss enamel to protect the decals. The model was then lightly weathered (using an airbrush, with thinned Floquil Grimey Black and Grime) since the Cincinnatian was a crack B&O passenger train and was keep clean with only the grime and soot accumulated from its daily run..

Scratchbuilt

The engine’s streamlined pilot, boiler, cab, handrails, trim and window frames are scratchbuilt, and also the tender body and frame were scratchbuilt. The decals were scratchbuilt using a computer.

Footnote

Phil’s model of the B&O P-7d 4-6-2 “Cincinnatian” #5301 won First Place in the “Scratch Built Steam Locomotive” and the “William J. Lenoir Memorial Award” for Best Scratch Built Steam Locomotive at the NMRA 75th National Convention in July 2010. A month before, at the MCoR 2010 Convention, this engine won First Place in the “Scratch Built Steam Locomotive” category and “Best of Show” in the merit judging.